1

Choose your setting

2

Choose your emerald

3

Review Your design

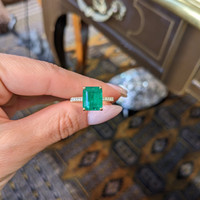

18K Yellow Gold Pave Ring Setting

Production Time: from 21 to 35 Days

Rush service may be available upon request

Item ID: JS1629

Free shipping

Price Calculated During Next Step

Quality, Value & Heart

100% Natural Emeralds

Free Shipping - Worldwide

14 Day No Hassle Return Policy

Supports Local Charities

Custom Designs Created With This Setting

Filter by

Loading data. Please wait...

Watch our process

Other Rings You May Like

Education About Emeralds

To truly appreciate and understand the beauty and wonder of an emerald, visit our education section where we explore the vast and fascinating world of emeralds!